-

PVC Tarpaulin

PVC tarpaulins is made of high strength polyester high-strength polyester canvas fabric, coated with polyvinyl chloride (PVC) paste resin with addition of variety of chemical additives, like DOP, anti-aging and anti-static components, etc.. PRODUCTS DETAILS: Material:pvc+ polyester fabric Weight:300gsm to 1500gsm Color:any colors is available Base fabric:1000D, 840D, 500D,etc Size:1.02-3.20m*50m, 1.02-3.20m*100m Surface:Glossy, Matte Life time:Minimum 2 years outdoor durability under normal application Packing:Craft paper packingor hard tube packing FEATURES: 1. Tear resistant 2. Water proof 3. Mildew proof, anti-aging 4. UV blocker/stablized(optional) Application: 1. General Cover, Construction and Machinery Equipment Cover. 2. Covers for open-stored goods, Covers for trucks/automobiles/boat. 3. Covers for Swimming Pools and Garden Furniture . 4. Lining materials for storage tanks and containers. 5. Lining material for irrigation Canals and grain silos. 6. Industrial Cover, Tents, Picnic mats. 7. Transportation in mineral factories and ports . 8. Used as tent in outside travel, picnic or emergency tent transportation in ports. 9. Used as cover for agriculture, garden cover, ground sheet. 10. For the construction buildings, prevent from dropping dangerous things. 11.Roof cover,etc.

-

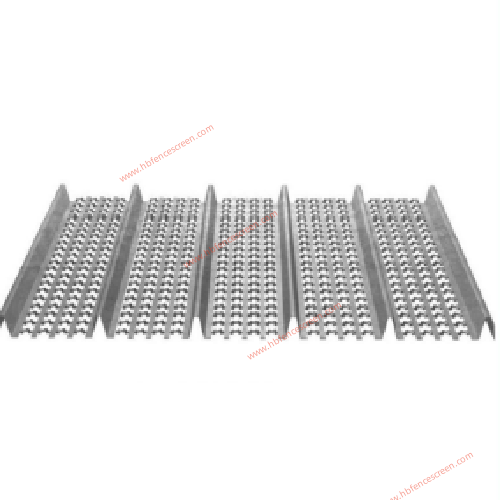

Expanded Permanent Formwork Mesh

Product Description: High Ribbed formwork is manufactured from hot-dipped galvanized steel sheets. Because its meshes and U patterns, it has better anti-stress capability and forming flexibility than normal metal lath. This product has excellent engineering quality, construction security and widely used in building construction to form retaining walls, columns, stop ends, construction joints and used to support slab flooring. Expanded Permanent Formwork Mesh High Rib Formwork Mesh Hy Rib Formstopfor Concrete Formwork Construction Hy-Ribbed Formwork is also known as Permanent Formwork, expanded Formwork. It is used as the consumable template. The edges of the open of the mesh will be inset in the concrete when the concrete pouring behind the formwork. That will be a mechanical wedge to link with the block. The quality of the joint can be strictly controlled. The strength of the adhesion and shearing can be equal to the excelletn rough cut stitching. There is no drilling, plucking and other process needed when do the secondary pouring. It can shor the construction time and at the same time make the concrete stronger.